O1/1.2510 Cold Work Tool Steel, Alloy Tool Steel,Oil Steel

.jpg)

Cold work tool steel/ oil steel O1

Equivalent grades: O1, 9CrWMn, 1.2510/100MnCrW4, SKS3

Chemical Composition:

|

C |

Si |

Mn |

Cr |

W |

V |

P |

S |

|

0.90-1.05 |

0.15-0.35 |

1.00-1.20 |

0.50-0.70 |

0.50-0.70 |

0.05-0.15 |

0.03MAX |

0.03MAX |

Available sizes: Round dia 16mm to 600mm; flat 16 - 400mm x 200 – 800mm

Smelting & Shaping: EF/ ESR+ hot forged/ hot rolled

Surface Condition: Black surface/ Grinded/ Machined

Delivery Condition: Annealed

Annealed Hardness: HB210MAX

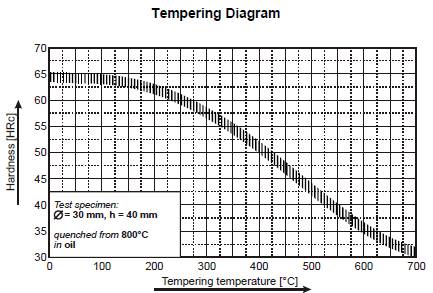

Hardness & Tempering Curve:

Characteristics:

High wear resistance

High surface hardness after tempering;

Good dimensional stability during heat treatment;

Good machinability

Applications:

Cutting and punching tools, shear knives, thread rolling tools, measuring instruments, platinum using molds.

(All technical information just for reference only)

Pre: DC53 Cold Work Tool Steel, Alloy Tool Steel

Next: DIN 1.2367 Hot Work Tool Steel, Alloy Tool Steel

>

>