DIN 1.2367 Hot Work Tool Steel, Alloy Tool Steel

Hot work tool steel 1.2367

DIN 1.2367/X38CrMoV5-3

Chemical composition:

|

C |

Si |

Mn |

Cr |

Mo |

V |

P, S |

|

0.35-0.40 |

0.10-0.40 |

0.20-0.40 |

4.70-5.20 |

2.70-3.30 |

0.40-0.70 |

0.03 max |

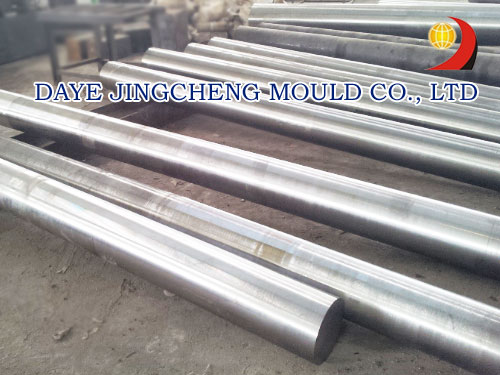

Available sizes: Round dia 16mm to 600mm; flat 16 - 400mm x 200 - 800mm

Manufacture: EFS/ESR, hot forged/ hot rolled

Surface condition: Black/grinded/rough turned/milled(machined)

Delivery condition: annealed/ quenched and tempered

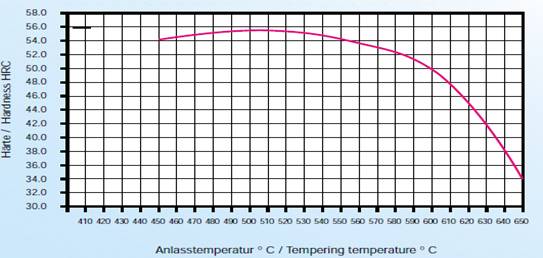

Hardness:annealed, 220HBS max/ hardness after quenched and tempered as per buyer’s requirement

8.

Characteristics: good macro and microstructure with lowest levels of segregation, very good polishability, good thermal conductivity, high dimensional stability during heat treatment, good machinability, high working hardness for increased service life.

Applications: heavy duty hot work tool and dies, mainly for light alloy processing: mandrels, dies, and containers for metal tube and rod extrusion equipment; tools and dies for the manufacture of hollow bodies, screws, rivets. Die casting equipments, forming dies, die inserts, hot shear blades, and plastic moulding dies.

(All technical information is for reference only.)

Pre: O1/1.2510 Cold Work Tool Steel, Alloy Tool Steel,Oil Steel

Next: AISI H10/DIN 1.2365 Hot Work Tool Steel, Alloy Tool Steel