DC53 Cold Work Tool Steel, Alloy Tool Steel

DC53 Cold work tool steel

Chemical Composition ( typical analysis% ):

|

C |

Si |

Mn |

Cr |

V |

Mo |

|

0.95 |

1.0 |

0.4 |

8.0 |

0.3 |

2.0 |

Available sizes: Round dia 16mm to 600mm; flat 16 - 400mm x 200 – 800mm

Smelting & Shaping: EF/ ESR+ hot forged/ hot rolled

Surface Condition: Black surface/ Grinded/ Machined

Delivery Condition: Annealed

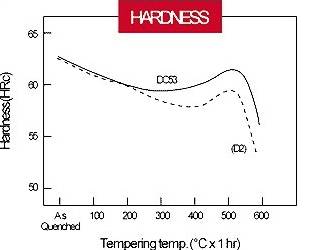

Hardness & Tempering Curve:

Characteristics:

Uniform distribution of fine carbides

Excellent galling & wear resistance

Exceptional toughness & fatigue resistance

High temper resistance to support PVD & nitride surface treatments

Machining & grinding characteristics superior to most other tool steels

after heat treatment, the hardness is higher than SKD11;tenacity is twice of SKD11; high hardness and toughness

Applications:

Punches & dies

Draw & forum dies

Shear blades

Shredder knives

Thread & form rolls

Cold heading dies

Mill rolls & slitters

(All technical information just for reference only)

Pre: D6/1.2436 Cold Work Tool Steel, Alloy Tool Steel

Next: O1/1.2510 Cold Work Tool Steel, Alloy Tool Steel,Oil Steel