NAK80 Plastic Mould Steel, Superior Mirror Mould Steel

Superior Mirror Mould Steel NAK80

Chemical composition: typical analysis(%)

|

C |

Si |

Mn |

Mo |

Cu |

Al |

P |

S |

Ni |

|

0.15 |

0.30 |

1.50 |

0.30 |

1.00 |

1.00 |

0.02 max |

3.0 |

|

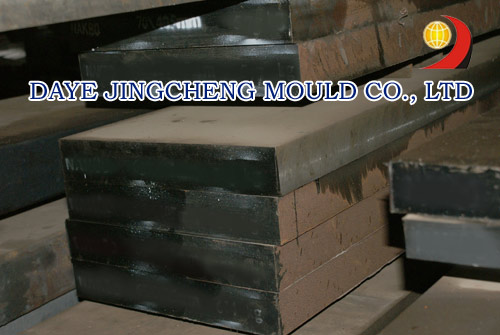

Available sizes: Round dia 16mm to 600mm; flat 16 - 400mm x 200 – 800mm

Manufacture: ESR, hot forged

Surface condition: black/grinded/rough turned/milled

Delivery condition: quenched and tempered

Hardness: after Q+T, hardness 38-42HRC

Characteristics:

super clean, ESR manufacturing process

age-hardened for uniformity of hardness throughout, even in heavy section

when welded, leaves no witness lines after re-aging

uniform grain structure with no pin holes, inclusions or hard spots

machines up to 20% faster than 30HRC P20 mold steels

never needs stress relieving, even after heavy maching

super polishability, even over welded areas

Applications:

clear lens molds

extremely critical diamond finish applications

molds requiring special EDM finish.

(All technical information is for reference only.)

Pre: DIN 1.2083 Plastic Mould Steel, Steel Flat, Steel Round Bar

Next: DIN 1.2738 Plastic Mould Steel, Steel Flat, Steel Round Bar