DIN 1.2083 Plastic Mould Steel, Steel Flat, Steel Round Bar

Mold Steel 1.2083

Equivalent grades: DIN 1.2083/ X42Cr13, 420, S136

Chemical composition:

|

C |

Si |

Mn |

Cr |

V |

P |

S |

|

0.38-0.45 |

0.30-0.50 |

0.20-0.40 |

12.00-13.50 |

0.18-0.30 |

0.03max |

|

Available sizes: Round dia 16mm to 600mm; flat 16 - 400mm x 200 – 800mm

Manufacture: EF/ESR, hot forged/ hot rolled

Surface condition: black/grinded/rough turned/milled

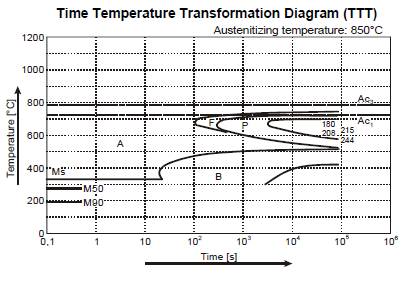

Delivery condition: annealed/quenched and tempered

Hardness: annealed, 229HBS max/ after Q+T, hardness 31-35HRC

Characteristics: good anti-rusty capacity, polishing capacity, super intensity and wearable capacity.

Applications: corrosion resistance and wear resistance of high quality plastic mould, transparent plastic mould.

(All technical information is for reference only)

Pre: DIN 1.3343 High Speed Tool Steel

Next: NAK80 Plastic Mould Steel, Superior Mirror Mould Steel