AISI H11/ DIN1.2343/ X37CrMoV5-1 Hot Work Tool Steel, Alloy Tool Steel

Hot work tool steel H11

Equivalent grades: GB4Cr5MoSiV, AISI H11, JIS SKD6,DIN 1.2343

Chemical Composition:

|

C |

Si |

Mn |

Cr |

Mo |

V |

P |

S |

|

0.36-0.42 |

0.90-1.20 |

0.30-0.50 |

4.80-5.80 |

1.10-1.40 |

0.25-0.50 |

0.03MAX |

0.03MAX |

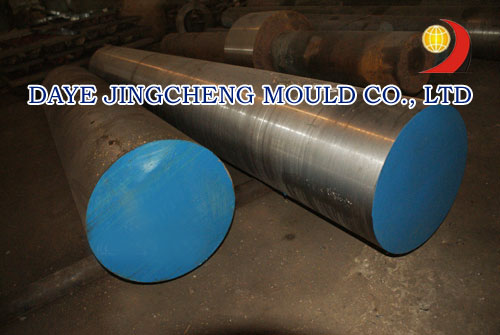

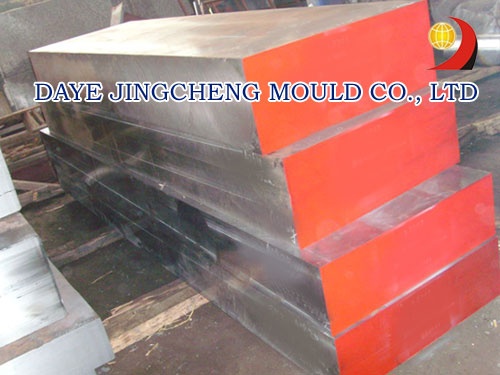

Available sizes: Round dia 16mm to 600mm; flat 16 - 400mm x 200 - 800mm

Smelting & Shaping: EF/ ESR, hot forged/ hot rolled

Surface Condition: Black/grinded/rough turned/milled(machined)

Delivery Condition: Annealed

Annealed Hardness: HB229MAX

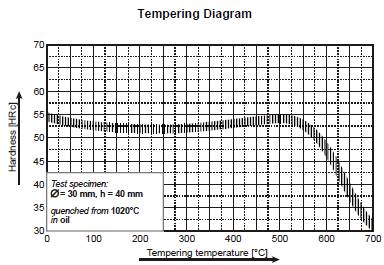

Hardness & Tempering Curve:

Characteristics:

Excellent homogeneity

Excellent toughness

High thermal ability

High resistance of thermal shocks

Applications:

Hot punches and dies for blanking, bending, swaging and forging, hot extrusion dies for aluminium, cores, ejector pins, inserts and nozzles for aluminium, tin and lead die casting.

(All technical information just for reference only)

>H11

>H11

Pre: AISI H10/DIN 1.2365 Hot Work Tool Steel, Alloy Tool Steel

Next: H13/1.2344/X40CrMoV5-1 hot work tool steel, alloy tool steel